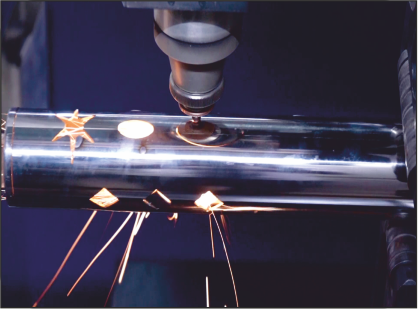

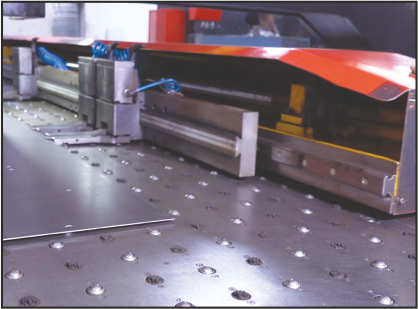

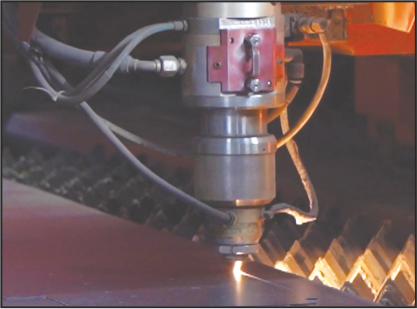

CNC : for cutting and bending

CNC (Computer Numerical Control) technology revolutionizes cutting and bending processes with precision and efficiency. By utilizing computerized controls, CNC machines offer unparalleled accuracy, ensuring every cut and bend meets exact specifications.

This technology enhances productivity, reduces material waste, and streamlines production timelines, making it an invaluable asset in various industries. With CNC for cutting and bending, intricate designs and complex shapes are executed with ease and consistency.

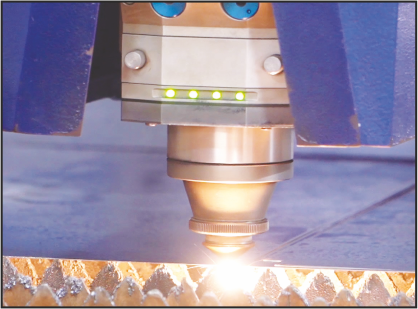

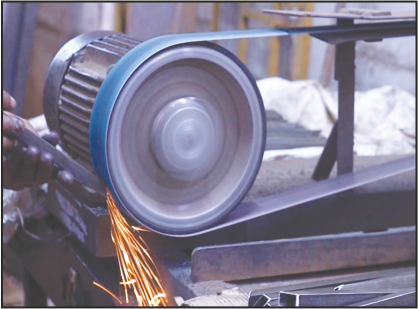

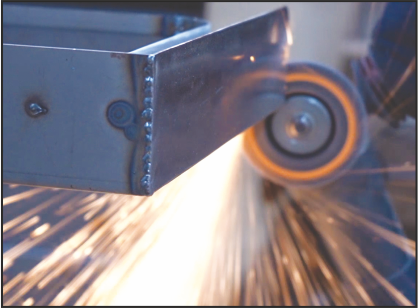

Computer-Aided Design & Computer Aided Manufacturing for quality finish

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) synergize to deliver exceptional quality finishes across various industries.

CAD enables designers to create precise 3D models of products or components, allowing for detailed visualization and customization. This technology facilitates the exploration of design iterations, ensuring optimal functionality and aesthetics before production begins.

This seamless integration of CAD and CAM streamlines workflows reduces production lead times, and minimizes errors, resulting in superior-quality finishes that meet or exceed customer expectations.